Water knife Mosaic is the use of a variety of stone using water knife cutting technology processing, and then put together a puzzle, called water knife Mosaic, and can also be called water knife puzzle, water knife art Mosaic, water knife art puzzle.

Stone parquet, in the building materials industry is a common word eye, but many people do not know how to produce a product, when a gorgeous and beautiful parquet presented in front of people, it in the production process but after many processes ah!

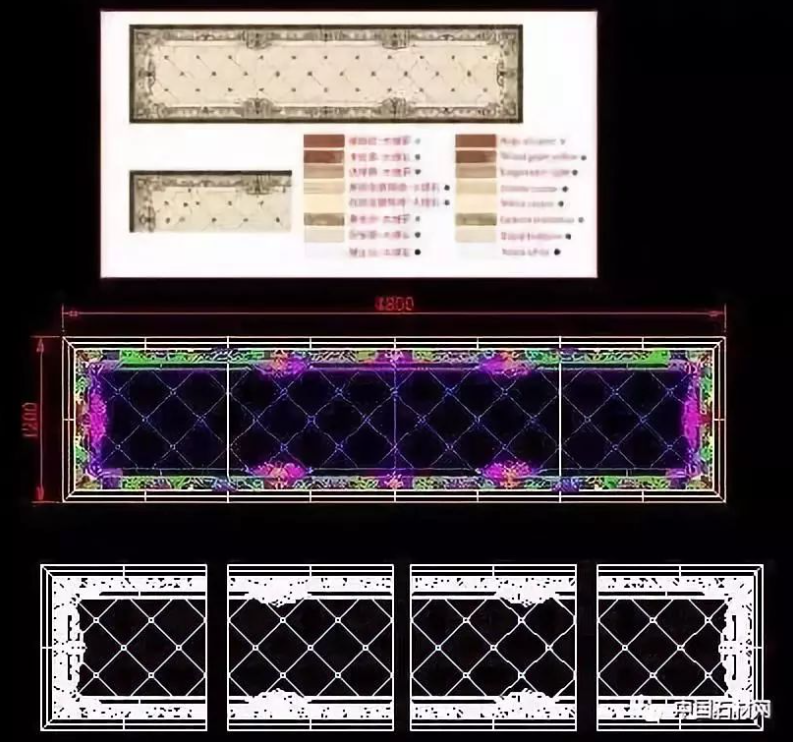

First of all, after the design department confirms that the color drawing is consistent with the customer, the color drawing and CAD line drawing are sent to the computer drawing room for computer production. Computer graphics include: 1. Layer, separate different colors of material. 2. Typesetting, the scattered parts are arranged regularly according to the size of the actual materials. 3. Process. 4. Compile. 5. Audit. 6. Produce the breakdown drawings.

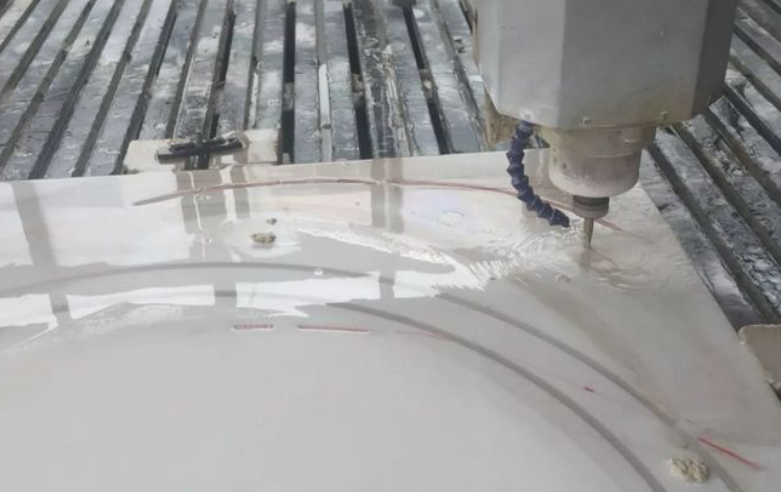

These six parts have a lot of details, such as: the processing part has the compensation of the water knife, the connection of each part, and the saving of the "DXF" file format. After the completion of computer drawing to water knife cutting, water knife cutting is a high-tech water jet cutting technology, can cut a variety of different materials of hard objects, such as stone, ceramics, steel, wood, insulation board and so on.

The cutter follows the computer drawing to enter the file path, and the water knife machine can automatically process all the objects shown in the drawing. The cutting is completed to the parquet process, which is a big process that is completely handmade. Before parquet, it is also necessary to polish the bottom edge of the cut out parts, so that it is easy to place when parquet, parquet must be tried according to computer drawings, that is, puzzle layout. After the completion of the test with AB adhesive paste, in order to make the surface of the figure flat, paste the surface of the figure is by the glass countertop, but also with iron block pressure type.

After the completion of the stone parquet test, it is shaped with resin. After the resin dries, it is placed on the thickness machine to set the thickness, complement the color, and then polished and cut the edge.

The stone parquet used on the ground, the surface is flat; The wall is used, there are flat and convex effects, and the convex effect is layered when pasted, the raised part is padded with Mosaic, and the surface is filled with caulk, and then it is clean. Finally to the packaging process.

Manual Collage

Parquet Patch

Stone parquet must undergo strict quality inspection before packaging, including the overall size, surface leveling, cleaning, seam alignment, color difference lines, etc., to meet the quality requirements of packaging. Because stone parquet is a fragile product, so the packaging requirements are also very high, to use transparent oil paper wrapped in the surface of the product, pre-imitation scratching, and then use foam edge sealing, to avoid damage, and finally fixed packaging with a wooden frame, marking the label, the entire production process is completed.

Stone parquet is the most fashionable and popular home decoration today, it makes your space different, more personalized, more tasteful! Also let you enjoy a noble and comfortable home life.

About Us

Jessie

Fortune East Stone

📧 Email: sales08@fortunestone.cn

📞 Phone: +86 15880261993

🌐 Websites: www.festonegallery.com | www.fortuneeaststone.com