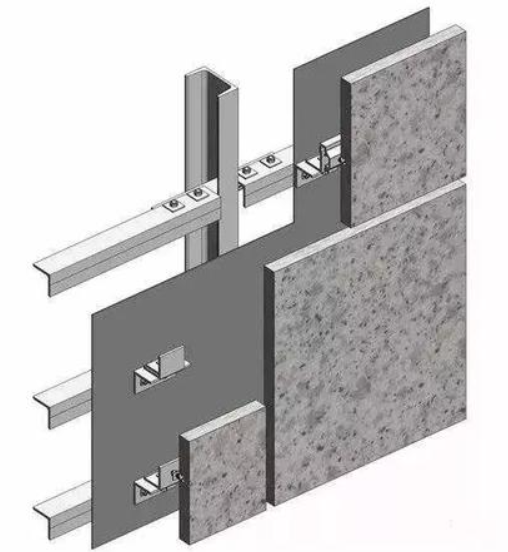

Stone dry hanging method, also known as empty hanging method, is a new construction technology in the decoration of contemporary decorative materials. Mainly used in the exterior wall installation of plates. The method is to use metal components to directly hang the decorative stone on the wall or empty hanging on the steel frame, without further grouting paste. The principle is to set the main force point on the main structure, and fix the stone on the building through the metal pendant to form the stone decorative curtain wall.

Dry hanging stone should do a good job of surface care, reduce water absorption, reduce the impact of external material pollution, corrosion and freeze-thaw, should be selected for specific stone surface treatment of appropriate protective agents, protective agents should meet the requirements of natural stone protective agents national standards.

Here are the operation processes:

1. Plate cutting

According to the requirements of the design drawings, cutting on the construction site, due to the large plate specifications, it is appropriate to use the stone cutting machine to cut, pay attention to keep the plate corners straight and regular. After the plate is cut, in order to make its corners smooth, a portable polishing machine can be used for grinding.

2. Drill holes and make slots

The adjacent plates are connected and fixed with stainless steel pins, and the pins are inserted in the side face of the plate. Hole diameter Φ5mm, depth 12mm, drill with electric drill. Because it is related to the installation accuracy of the plate, the drilling position is required to be accurate. Due to the self-weight of large size stone, in addition to the steel members to support the plate under the mouth, but also need to be slotted in the middle of the plate to support the weight of the plate.

3. Apply water repellent

Apply a layer of polyacrylic waterproof coating on the back of the plate to enhance the waterproof performance of the exterior surface.

4. Wall finishing

If there is a partial bulge on the surface of the concrete exterior wall that will affect the installation of the fastener, it must be chiseled and trimmed.

5. Play the string

Lead out the floor elevation and axis position from the structure, pop out the horizontal and vertical control lines of the installation plate on the wall, and make a gray cake to control the flatness of the installation plate.

6. Brush with water repellent

Since no mortar is filled between the slab and the concrete wall body, in order to prevent leakage that may be caused by material properties or construction quality, a layer of waterproofing agent is painted on the outer wall. To strengthen the waterproof performance of the external wall.

7. Plate installation

The sequence of installation plates is carried out from the bottom up, and two horizontal control lines are pulled at the upper and lower mouth of the installation position of the last row of plates on the wall, and the plates are installed from the middle or the sunny corner of the wall. First install the first piece as a benchmark, its flatness is based on the grey cake set in advance, and the line is suspended straight and fixed after calibration. After a row of plates is installed, the previous row of fasteners are fixed and installed. The four corners of the plates are required to be flat and the joints are vertically and horizontally.

8. Plate fixation

The steel fastener and the wall body are fixed with expansion anchor bolts. The fastener is a flat steel plate with bolt mounting holes and pin holes drilled. The fastener is adjusted according to the installation distance between the wall and the plate. The holes on the fastener are oval, so as to adjust the position during installation.

9. Waterproof treatment

The waterproofing of the stone surface joints is done with sealed silica gel caulking. Before caulking, a flexible strip foam polyethylene material is embedded in the gap as a substrate to control the sealing depth of the joint and strengthen the bonding force of the sealant.

About Us

Jessie

Fortune East Stone

📧 Email: sales08@fortunestone.cn

📞 Phone: +86 15880261993 (Available on WhatsApp)

🌐 Websites: www.festonegallery.com | www.fortuneeaststone.com