The global stone industry is standing at a fascinating crossroads. Driven by technological leaps, evolving design philosophies, and an unwavering focus on sustainability, the sector is transforming from a traditional extraction trade into a high-tech, eco-conscious design partner. For architects, designers, contractors, and homeowners, understanding these shifts is not just academic—it’s essential for making informed, future-proof decisions. Let's dive into the latest developments reshaping the world of natural and engineered stone.

1. The Sustainability Imperative: Beyond the Quarry

The conversation around sustainability has moved far beyond simple recycling. It now encompasses the entire lifecycle of stone, from quarry to installation and end-of-life.

Carbon-Neutral Quarrying: Leading producers, particularly in Europe and North America, are investing heavily in electrifying quarry machinery. Solar-powered saws and loaders are moving from pilot projects to standard operation, significantly reducing the carbon footprint at the source. Some Italian and Brazilian quarries now publish "Environmental Product Declarations" (EPDs) for their blocks, offering full transparency on embodied carbon.

Circular Economy Models: The industry is tackling waste with new vigor. Off-cut stone, once destined for landfill, is now systematically collected and crushed for use in terrazzo, landscaping, or as a raw material for new binding agents. Companies like StoneCycle are pioneering methods to repurpose silica-rich stone dust into additives for concrete, reducing the need for virgin materials.

Water Reclamation Revolution: Water used in cutting and polishing is no longer seen as waste but as a resource. Closed-loop filtration systems that recycle up to 95% of process water are becoming a non-negotiable standard for responsible fabricators. This not only conserves a vital resource but also drastically reduces water pollution.

2. The Digital Fabrication Frontier: Robotics & AI Take Center Stage

The shop floor is getting a digital brain. Automation is no longer just about large gantry saws; it's about integrated, intelligent systems.

AI-Powered Yield Optimization: New software platforms use artificial intelligence to analyze slab images. By identifying veins, fissures, and color variations, the AI suggests cutting patterns that maximize material usage, sometimes improving yield by 15-20%. This reduces waste and boosts profitability.

Robotic Polishing and Finishing: Collaborative robots ("cobots") are working alongside human technicians. These robots handle repetitive, precise tasks like edge polishing or intricate surface texturing, ensuring unparalleled consistency and freeing skilled workers for complex design and quality control.

3D Scanning for Perfect Fit: On-site 3D laser scanning of spaces (like complex kitchen walls or curved facades) allows for the creation of digital twins. These precise models enable fabricators to pre-cut and dry-fit stone cladding or countertops with millimeter accuracy, minimizing on-site adjustments and installation time.

3. Engineered Stone 2.0: The Next Generation

The engineered quartz (QE) segment is undergoing its most significant evolution since its inception, responding to both market demands and regulatory pressures.

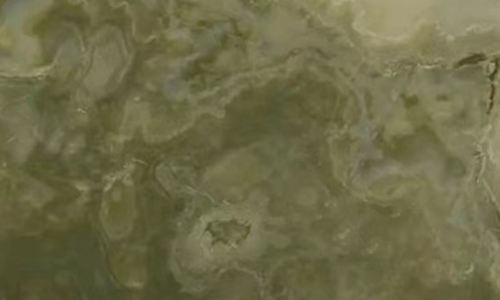

The Rise of "Flexible Stone" Veneers: Ultra-thin (1-3mm) natural stone veneers backed with fiberglass or polymer resins are creating waves. This material offers the authentic beauty of marble or travertine with drastically reduced weight, making it ideal for retrofitting over existing surfaces and for high-rise applications where load is a concern.

Enhanced Durability & Porosity: New resin formulations and sintering technologies are producing surfaces that are more scratch, stain, and heat-resistant than ever. Some new lines boast near-zero porosity, making them as maintenance-free as their natural counterparts, if not more so.

Bio-Based Resins: In response to health and environmental concerns around traditional binders, several manufacturers are launching lines using resins derived from plant-based sources (like linseed oil or soy). This addresses the demand for healthier indoor air quality and more sustainable composite materials.

4. Design Trends: The Return of Drama and Texture

In interior design, stone is making a bold statement.

Super-Format Slabs: The demand for seamless, dramatic statements continues. Slabs now commonly reach sizes of 130" x 65" and beyond, minimizing joints in large kitchen islands, shower walls, and feature walls. This trend pushes fabricators and installers to new levels of logistical and technical skill.

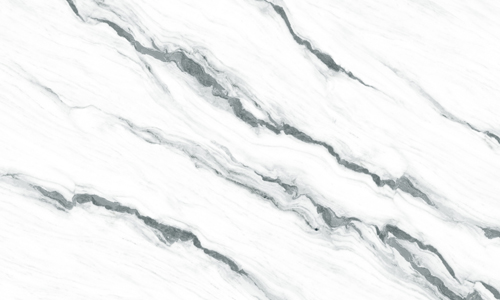

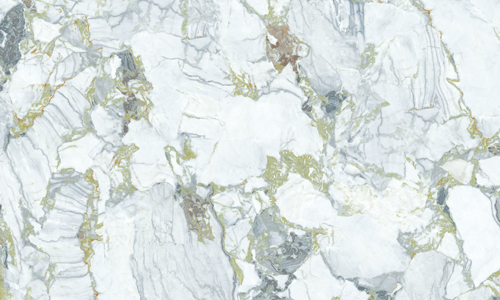

Textured, "Tactile" Finishes: The reign of the high-gloss polish is sharing the stage. Flamed, bush-hammered, sandblasted, and honed finishes that highlight the stone’s natural texture are hugely popular. These finishes add visual depth, provide safer slip-resistance, and celebrate stone’s organic origin.

Book-Matching and Vein-Matching: Using consecutive slabs from a block to create symmetrical, mirror-image patterns (book-matching) is now a baseline for luxury projects. The next level is full-wall or multi-slab "vein-matching," where the natural veining is continued across several slabs to create a breathtaking, mural-like effect.

5. The Supply Chain & Geo-Political Landscape

Global dynamics continue to influence availability and cost.

Near-Shoring & Regional Sourcing: Volatile shipping costs and a desire for shorter, more transparent supply chains are leading many specifiers in North America and Europe to prioritize stone from regional quarries. This has boosted interest in locally sourced limestone, granite, and slate, celebrating regional geology.

Transparency & Traceability: Blockchain and QR code technology are being piloted to track a slab's journey. By scanning a code, a buyer can see the quarry of origin, processing history, and carbon footprint data, verifying ethical sourcing and sustainability claims.

Tariff Fluctuations: Ongoing adjustments in international trade policies, particularly affecting imports of quartz surfaces and marble from certain regions, are causing fabricators to maintain more diverse material portfolios to ensure price stability for their clients.

Conclusion: Building with Vision

The stone industry in 2025 is defined by a powerful synergy: the timeless, unique beauty of natural stone is now amplified by cutting-edge technology and a profound responsibility towards the planet. For anyone embarking on a project, the key takeaway is to engage with partners who are fluent in this new landscape.

Ask your supplier or fabricator about their water reclamation practices. Discuss how digital templating can streamline your installation. Explore the possibilities of next-generation engineered materials or the dramatic impact of book-matched natural stone.

The future of stone is not just carved from the earth; it's being designed with intelligence, crafted with precision, and built with a legacy of sustainability in mind. The materials for breathtaking, responsible design are here—it’s time to build.

Contact Us

Silvia | Fortune East Stone

📧Email: sales05@fortunestone.cn

📞Phone/Whatsapp: +86 15960363992

🌐Websites: www.fortuneeaststone.com